It’s time to look beyond the screen on the wall! Getting digital signage in Canada is now one of the smartest ways for businesses to communicate, engage, and adapt in a fast-changing world. That’s why business owners across the country are asking: what is the future of digital signage, and is it worth investing in now?

At National Neon Signs, we’ve watched digital signage evolve from static displays into dynamic, data-driven platforms. Today, we’ll explore the trends shaping its future and how your business can prepare to reap the benefits.

Trends Driving the Future of Digital Signage

Digital signage has been around for years, but the next generation is about smarter, more interactive experiences. The biggest shifts underway include:

- Smarter Content Delivery: AI-driven systems tailor messages to customer profiles, weather, or even the time of day. For example, menu boards may update automatically at lunchtime.

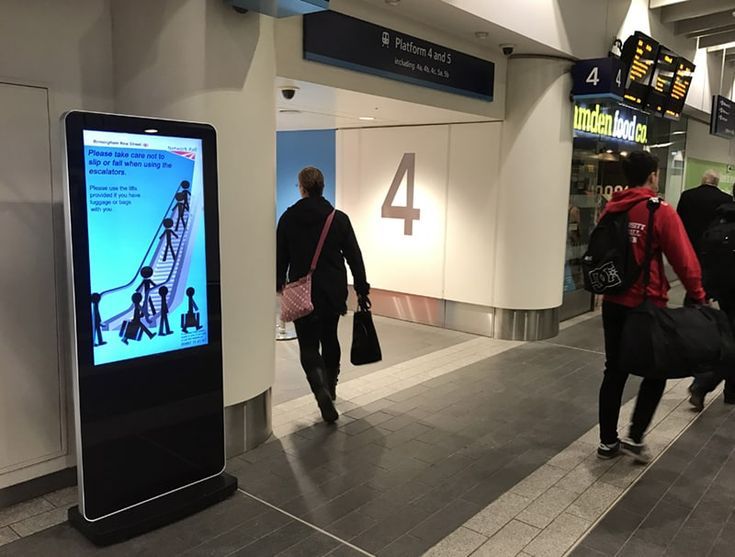

- Interactivity: Touchscreens, QR codes and mobile integration are transforming how we use digital signs. Now they don’t just promote a message—they act as two-way communication tools.

- Cloud-Based Control: Cloud platforms make it easy for businesses with multiple locations to update content in real time. It doesn’t matter if you’re managing one screen or one hundred.

- Integration with IoT: Sensors and live data feeds allow signs to display real-time updates such as transit schedules, inventory levels, or event notices.

Still relying on static posters? If so, you could be missing out on opportunities to engage customers. At National Neon Signs, we help businesses modernize with scalable, cloud-based systems that keep them ahead of the curve.

How Technology is Enhancing Digital Signs

While new software is taking over the industry, hardware is also advancing quickly. Here’s what’s new:

- LED Advancements: Because LEDS in digital signage are becoming brighter, displays are lasting longer and are more energy efficient than ever.

- 4K & 8K Displays: Ultra high-resolution displays are displaying clear images that capture the attention of anyone passing by.

- AR & VR Integration: Augmented and virtual reality are letting brands create a more immersive customer experience as time passes.

- Sustainability: Eco-friendly materials and lower power consumption are letting signs become greener and more cost-effective than before.

Besides looking impressive, these signs also deliver lasting value. Businesses that adopt new techniques tend to have longer-lasting signage that runs more efficiently and delivers a higher return on investment.

Benefits That New Digital Signs Can Offer a Business

Choosing digital signage has offered many benefits in the past, but there will be even more in the future. You get the following advantages of digital signage to your business:

- More Personalized Engagement: When you add dynamic content to a digital sign, your message will better resonate with your target audience.

- Better Customer Experience: Between wayfinding in hospitals and live promotions in retail, digital signs are the perfect combination of convenience and clarity.

- Operational Efficiency: Multi-location businesses are the best way to push updates while cutting back on printing, shipping or installation costs.

- Long-Term Savings: While the upfront investment might be higher, digital signage is an effective way to save money over time.

Many of our Canadian clients who grew tired of reprinting menus and posters now see digital signage as essential. The shift is no longer “Is it worth it?” but “Why didn’t we do this sooner?”

The Future is Bright for Digital Signage

What is the future of digital signage? With time, it’s become smarter, more interactive and more cost-effective than others. AI personalization, cloud-based control and eco-friendly designs are giving businesses years of benefits. At National Neon Signs, as the leading digital signage company in Canada, we help Canadian businesses unlock the future of digital signage through professional, durable solutions built for growth.

Ready to embrace the future of digital signage? Contact us to schedule a consultation and to get a custom quote!